| Electric curing oven | |

| Assembled Cabin system | - Outsize: 2.4m(H) * 2.3m(W) * 1.9m(L), one-side open - 1 inner rail, 1 outter rail -4 wheels and 2 mudsills for workpiece trailer made by customer |

| 24KW Full automatic electric heating system | - stainless steel electric heating tube |

| - temperature and holding time are automatically digital control - The temperature is automatically raised to the set temperature, and then set the time of the heat preservation .Automatic alarm after completion. | |

1. Assembled structure, convenient to transport.

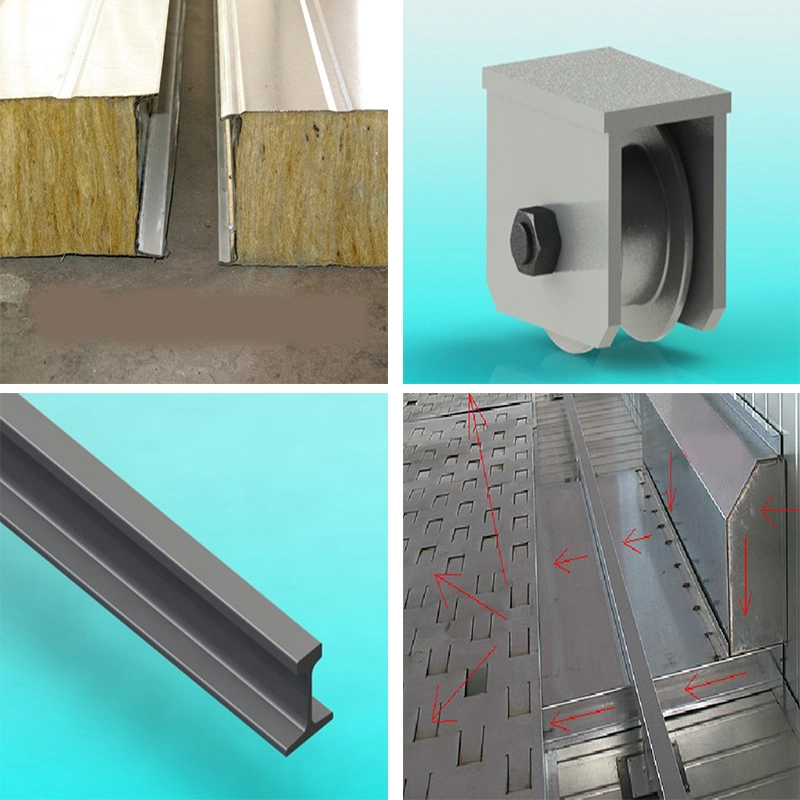

2. High density and high quality wool insulation, uniform density, good heat-insulation effect, the thickness of insulation layer is 100mm.

3. The inner material of Insulation board is galvanized sheet, a gray white spray plate for insulation board exterior.

4. The thermal insulation boards are under closed plug style, air-proof, good heat-insulation effect.

5. There are punched holes on the sidewalls of insulation boards as "Thermal bridge" , reducing the heat loss during transmission between inside and outside walls.

6. The door and door case of oven sprays heat - resistant paint, during a long time using can not occur scorches,discolor,smoking,falls off and any other problems.

7. n the curing oven we set up heat - resistant sealed strip to improve heat-insulation effect.

8. Our unique automatic-lifting design is used on the lock of oven. 2 mounting parts are setting on top and bottom and lock points won't touch the tracks when opening the door.

9. The weight of curing oven inner track transfer the weight to the ground through special structure, and it doesn't crush the bottom of insulation layer.

10. Both sides of curing oven can open, it set up outter track by outside, 2 parts of workpiece get into the curing in turn to improve work efficiency.

11. Standard collections of curing oven: inner track,outter track,2 heat-resistant wheels and floor beams( for customer self-made trailer ).

12. In the inner of gas,fuel,fire coal curing oven, we set up independent adjustable multiple spots vent, in order to distribute the inner temperature.

13. The reasonable distribution of stainless steel heating tubes with radiation fins let work pieces heated evenly in the oven.

14. Control cabinet of electrical heating oven:

The temperature in oven and the holding time are all controlled automatically. When the temperature in oven reaches the setting temperature, the heating work will be stopped and there will be an automatic.