Flame Resistant Urea Formaldehyde Resin Powder For Making Electrical Switch

Other name: Urea molding compound

Produced from Urea-formaldehyde resin and highy refined alpha-cellulose, Urea molding compounds createscrach-resistant lystrous

moldings that are highly resistant to detergents, oils and greases.

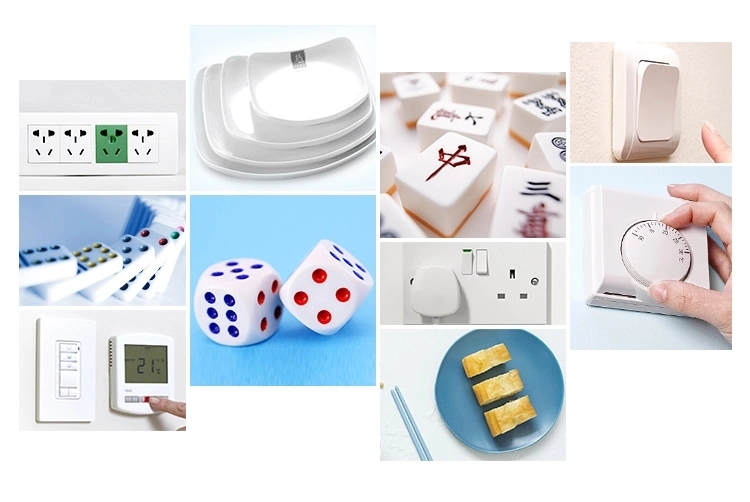

Application:

urea molding compounds is perfect for a wide range of household and commercial products, especially when color, feel amd cosmetic appearance, along with the durability necessary for everyday handing, are crucial. Some applications well-suited include: Electrical wiring devices, buttons, circuit protection devices. Appliance hardware, sanitary ware, small housings, cosmetic closures, game accessories.

Appearance:

Urea molding compounds is available in an unlimited range of colors. Appropriate for both compression an injection molding, our compounds are available in powder and in granule form.

Advantage:

As compared to thermoplastics, urea molding compounds exhibit:

1. Self-extingguishing flame resistant characteristics that will not support flame or melt

2. Siperior chemical resistance

3. Excellent electrical properties, including current tracking and arc quenching inherent antibacterial properties.

Product Information:

Powder or granular, having beautiful coloring, color stability, and wide palette range, Urea Formaldehyde Moulding Compound can be freely selected. With sub-easy mobility and thick fluidity, Urea Formaldehyde Moulding Compound can adapt to membrane and molded plastic needs.

Urea Formaldehyde Moulding Compound has mechanical properties, such as impact resistance, non-friable, high hardness, and good finish. With permanent antistatic properties, Urea Formaldehyde Moulding Compound is excellent arc resistance and tracking resistance.

| Model | UF1P-C | UF1G-C | UF1I-C |

| fluidity | 140-200 | 140-200 | 140-200 |

| Volatile matter | 1.0-2.0 | 2.0-3.0 | |

| Volatile matter | 4.0 | 4.0 | 4.0 |

| Apperance | The surface of the product has a smooth brightness, no bubbles and cracks, and the color and impurities meet the standard. | The surface of the product has a smooth brightness, no bubbles and cracks, and the color and impurities meet the standard. | The surface of the product has a smooth brightness, no bubbles and cracks, and the color and impurities meet the standard. |

| Boiling water resistance | No surface rot, allowing slight wrinkles and slight fading | No surface rot, allowing slight wrinkles and slight fading | No surface rot, allowing slight wrinkles and slight fading |

| Bending strength Mpa | 80 | 80 | 80 |

| Impact strength (notch) KJ/m2≥ | 1.8 | 1.8 | 1.8 |

| Heat distortion temperature °C ≥ | 115 | 120 | 120 |

| Water absorption (cold water) mg ≤ | 70 | 100 | 100 |

| Mold shrinkage, % | 0.6-1.00 | 0.6-1.00 | 0.6-1.00 |

| Insulation resistance MΩ after 24h in water ≥ | 104 | 104 | 104 |

| Dielectric strength, MV/m ≥ | 9.0 | 9.0 | 9.0 |

| Resistance tracking index, V ≥ | 600 | 600 | 600 |

| Heat resistant, grade | I | I | I |

Application

Melamine is an organic compound that can be combined with formaldehyde for making melamine resin, this is a synthetic polymer that is fire resistant and withstand high teperatures. Melamine resin may be used in many aplications and has a very stable structure. It is widely used in wood,plastic,paint,textile,leather,electronic,medical related fields etc.

25kg per kraft paper with PP inner. 22 metric tons per 20GP.

Welcome To Xiamen Shuanghaijin International Trade Co., Ltd. We are professional manufacturer and exporter of melamine powder for making tableware. Our factory is located in Ganzhou City, Jiangxi Province, China. Our factory covers an area of 80,000 square meters, We have over 1000 employees, has a large annual sales which is over 67 million US dollars. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee all customer's requestion. Becuase of our high quality and after-sales service, we have gained many global customers from South America, Eastern Asia, Southeast Asia, Middle East, Africa.

We are specialized in the production of amino plastic powder (mainly to plastic electric appliance), melamine molding powder(mainly to make plastic melamine tableware), and melamine glazing powder.What's more, we has two production lines of formaldehyde, which has a large output 100,000 tons. The capacity of melamine molding powder reaches to 20,000 tons per year. The capacity of urea molding powder is 50,000 tons per year. And we have a 1000-tons output of glazing powder. Glazing powder is used to polish the surface of tableware. In China market, we occupy the biggest market share. We sell melamine molding powder 1,800 tons in average per month, and melamine glazing powder 300 tons in average per month.

Why Choose Us?

Exporter and suppler of melamine moulding powder, melamine moulding compound, glazing powder, melamine tableware, melamine dinnerware, etc.

2006-2020 Professional melamine powder and melamine tableware manufacturer in China.

Our factory was established in 2006, and we are professional from blending color, production and sales in melamine moulding powder and melamineware.

FAQ

1. How can I trust you?

We are Verified Supplier; Trade Assurance Credits US $855,000.; AAA Credit Grade; Level 7 of Transaction.

2. Are you factory or trading company?

We are trading company with our own factory.

3. How do you ensure your product and service quality?

All of our processes strictly adhere to ISO-9001 procedures, and we have 12-18 months quality warranty against BL issue date.

4. How about delivery?

Mainly contains FOB, CIF, DDU.

5. How about the payment?

We support most mainstream payment methods. T/T, L/C, D/P,D/A, O/A.

6. Do you support sample?

Yes, we do. Please feel free to chat with us for specific requests.

Serivce

1.Sample available; accept trail order.

2.ODE&OEM are welcome.LCL/OEM/ODM/FCL.

3.If you want to import some products to test the market, we can lower the MOQ .

4.Welcome to contact us!