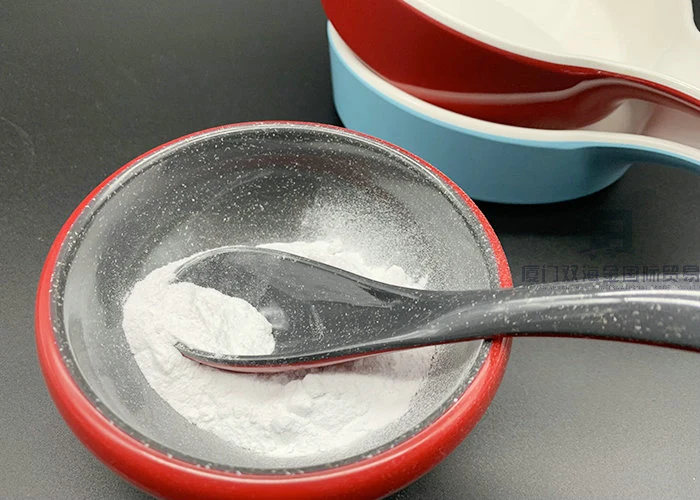

Melamine moulding compound (powder) (MMC):

1, For making Melamine tableware

2, Pure Melamine Food grade

3, Unlimited colors

Specifications

Name: Melamine

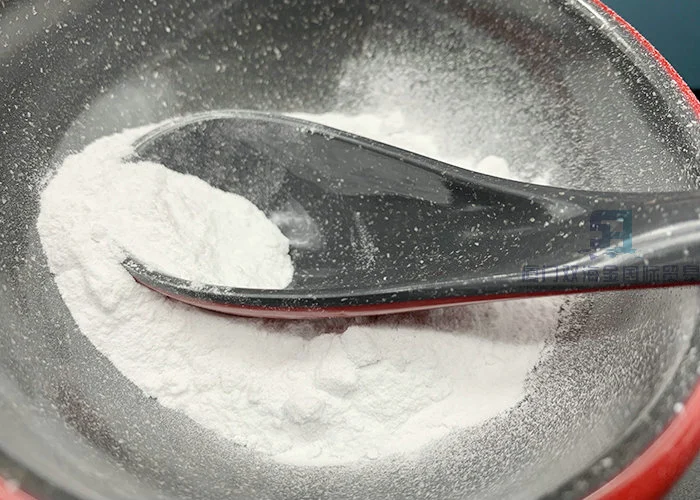

Appearance: White Powder

Grade: 99.8%min industrial grade

Package:25 kg/bag or Ton package

CAS:108-78-1

Melamine moulding compound

· E.U Food Standard

· Pression Moulding Temperature:165-185 °c

· Curing time:35-50'S Flowing rate:194

· Color : Unlimited range of colors

· Compression moulding powder

· 20/25kg Paper bag with inner waterproof PE film

· Min Order Quantity : 5 MT per color

· Delivery lead time :15 days

Advantage :

1, Melamine moulding compound finished item with surface hardness .

2, Molded parts have excellent resistance to abrasion, boiling water, detergents, weak acids ,

3, Moulded articles are specifically approved for food contact.

Physical property :

Melamine moulding compound are based on melamine-formaldehyde resins fortified with high-class celluloseas reinforcement and further modified with minor amounts of specialpurpose additives, pigments, cure regulators andlubricants.

Storage:

To avoid moisture caking, storage time should be placed away from the hot and humid environment,

generally at 30 degrees to 50% relative humidity storage conditions,

our products can be maintained around a one-year period.

CERIFICATE OF ANALYSIS

| 1 | Gravity | D2525,≤ | 1.6 | GB1033 |

| 2 | Specific volume | ml/g≤ | 3 | |

| 3 | Volatile matter | %,≤ | 3.8 | GB/T13455 |

| 4 | Water absorb (cold) / (hot) | mg,≤ | 50/65 | GB1034 |

| 5 | Shrinkage | % | 0.65 | GB13454 |

| 6 | Distortion temperature | °O,≥ | 155 | GB1634 |

| 7 | Flowing | mm | 194 | GB13454 |

| 8 | Impact Strength(notch) | KJ/m2,≥ | 1.9 | GB1043 |

| 9 | Bending Strength | Mpa,≥ | 80 | GB9341 |

| 10 | Insulation Resistance after 24h in water | MΩ≥ | 105 | GB1410 |

| 11 | Dielectric strength | MV/m,≥ | 9.0 | GB1408 |

Application

Melamine molding compounds is suitable for both compression and injection molding and are available in fine powder and granular forms,And in an unlimited range of colors.

UF and MF molding compounds can be used to produce many products.

1. Kitchen utensils and kitchen ware, imitation ceramic dinnerware, tableware (plates, cups, mugs, saucers, ladles, spoons,bowls and dishes), melamine crockery.

2. Entertainment products, such as dominoes, dice, mahjong, chess and so on.

3. Daily necessities: imitation porcelain, resin craft, imitation pearls, ashtray, coat buttons and pins, sanitary accessories, toilet seat.

4. Electrical appliance: switch, sockets, wall-plates, MCB, wiring equipment, lamp holder, electric lamp socket, relay, plug outlet connector.

Our Services

A) Storage life: 6 months under temperature lower than 30° C

B) The goods should be stored in a dry, ventilated location. Avoid direct sunshine and moisture

C) The package should be sealed again immediately once the pack has been opened to avoid moisture

Transportation:

Plastic woven bag with inner moisture proof polyethylene bag. Kept in airy, dry and cool place.

Storage period: six months from the manufacturing date.

Transportation Caution: avoid moisture, heat, dirt and packaging damage.

20 feet full container load=20 Metric Tons

Company Profile

Our company is located in the National Hi-Tech Industrial Development Zone of XIAMEN City, Fujian Province.

The company takes "high quality, high efficiency, high reputation, Xingguo, Xingjia, Xing Enterprise" as its business philosophy, adhering to the enterprise spirit of "pursuit of perfection, truth-seeking and innovation", and is willing to satisfy customers with the best products, thoughtful and timely after-sales service. Requirements!

We are willing to work together with customers at home and abroad to create a better future!